Thermal Management System

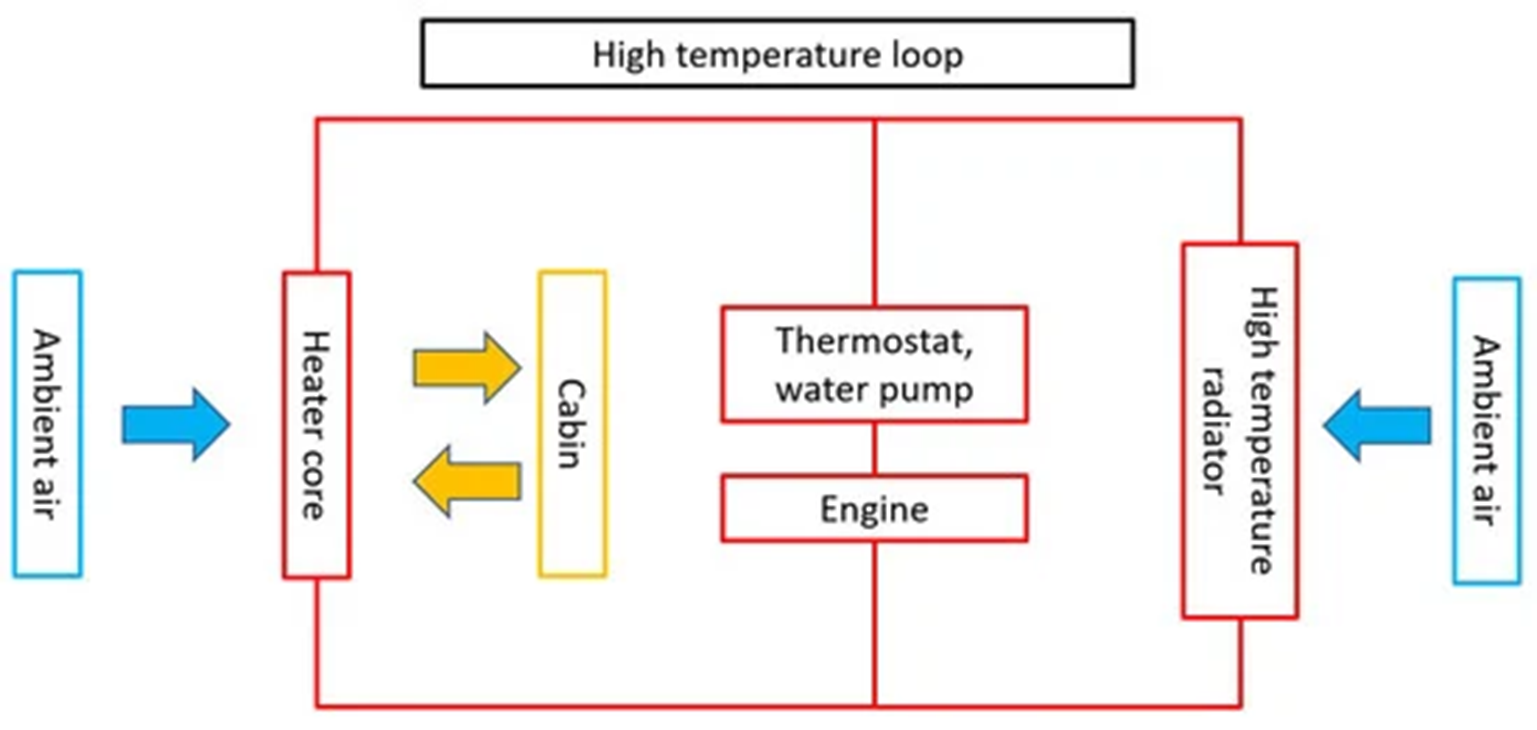

High Temperature Loop

- Maintaining the IC engine in its optimal temperature range in wide range working conditions, including transient conditions

- Particular attention has to be paid to avoid overheating in any condition

- Reduce exhaust pollutants

- Reduce oil viscosity by reducing warm up time and maintaining a correct temperature

- Reduce power dissipation in engine auxiliaries, such as pumps and fans

- Improve combustion boundary conditions

- The reduction of engine and lubrication oil warm up time has a series of beneficial consequences

- Reduction of fuel consumption

- Reduction of friction losses

- Reduction of CO2

- Significant reduction of pollutant emissions in test cycles

- Possible reduction of NOx in Diesel engines

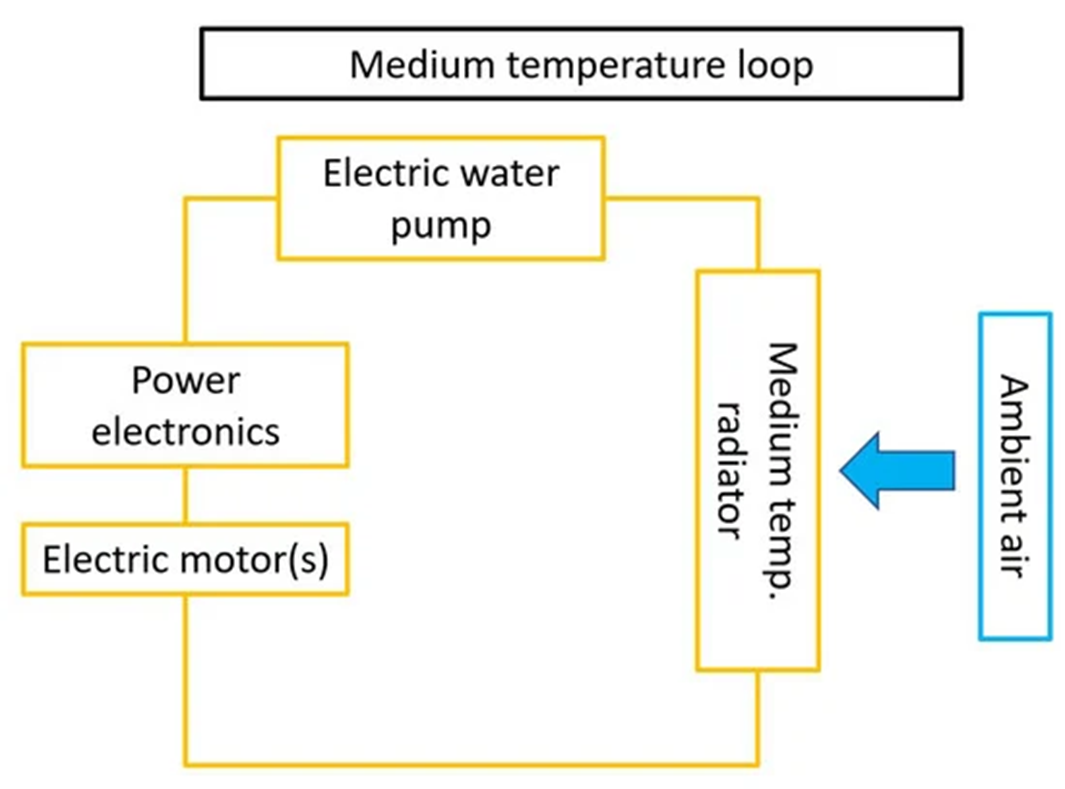

Medium Temperature Loop

- In most cases, due to the high efficiency of electric machines, the exchanged heat is not sufficient for cabin heating.

- The electric machine working temperature is of the order of 60 °C, and, in most climates, conditioned air is not needed for cooling.

- The medium temperature loop can exchange heat with high and/or low temperature loop.

- In cold weather, the wasted heat can be used to speed up the engine warm up or battery heating

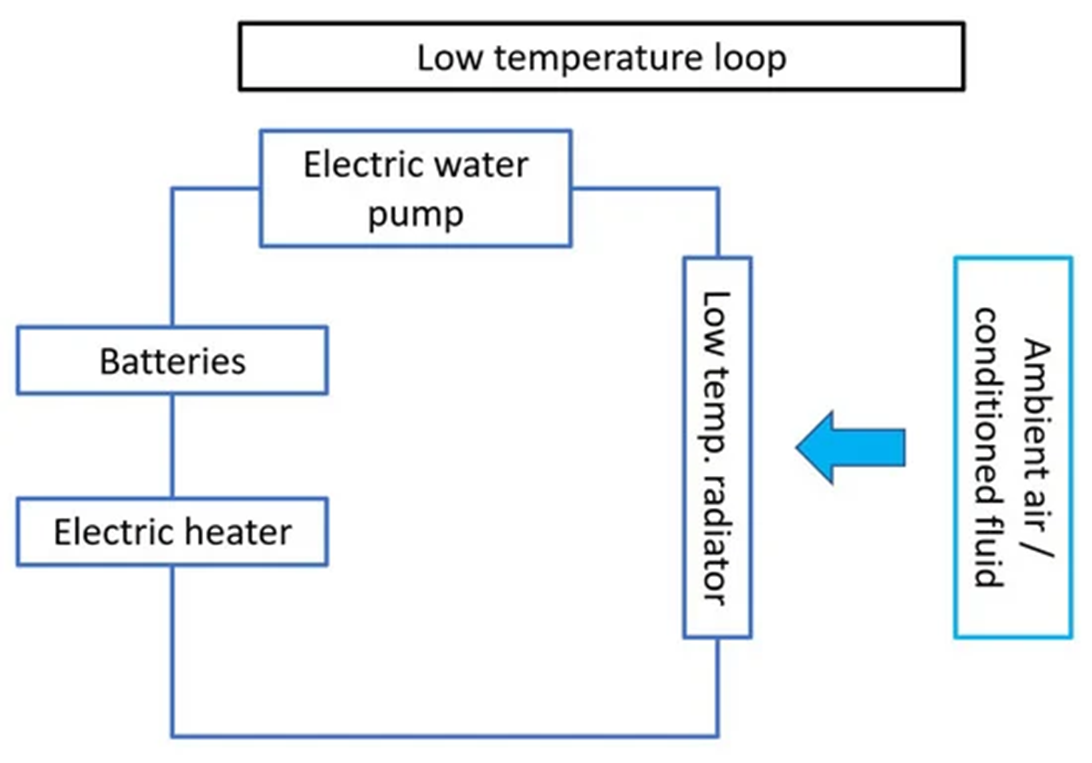

Low Temperature Loop

- In this case, a liquid cooling system is considered, however, this is not the only possibility as air cooling is also used for batteries

- In any case, depending on the ambient temperatures, conditioned air could be used for heat removal and a battery heater may be necessary.

- The cabin conditioning loop and the low temperature loop have very similar target temperatures, therefore, in some applications, the two loops are strictly connected and just one conditioning machine is employed

Further Reading Reference

Click to view link or Scan QR Code to read Research Review Paper

[https://www.mdpi.com/1996-1073/15/4/1326]